For larger notch radii use the values of q shear corresponding to. Spur gears can handle high.

Unit Ii Design Of Shafts And Couplings

The rotating shaft is required for closed-tank operation and the type depends on degree of seal required operating pressure and operating temperature.

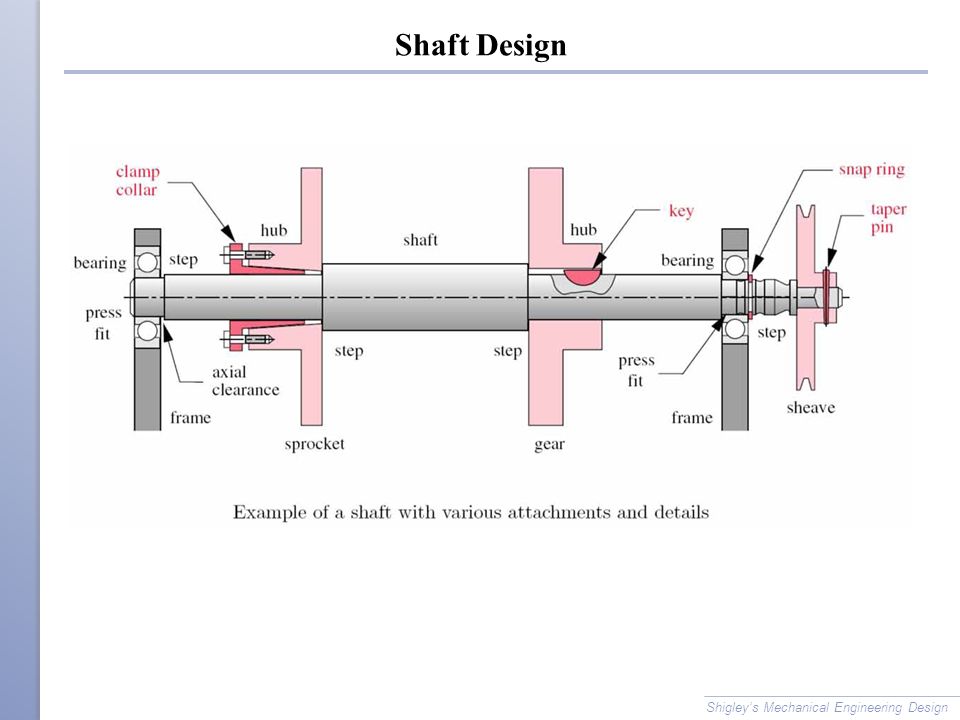

. Spur gears are by far the most common type of parallel-shaft gear. Shaft Design Objectives Compute forces acting on shafts from gears pulleys and sprockets. 1 August 15 2007 1 17.

The design of the composite drive shaft is divided into two main sections. Loads on shaft due to pulleys Torque and Bending moment diagrams for the pulley system Power toque speed For linear. A propeller shaft is an assembly of one or more tubular shaft connected by universal constant velocity or flexible joints.

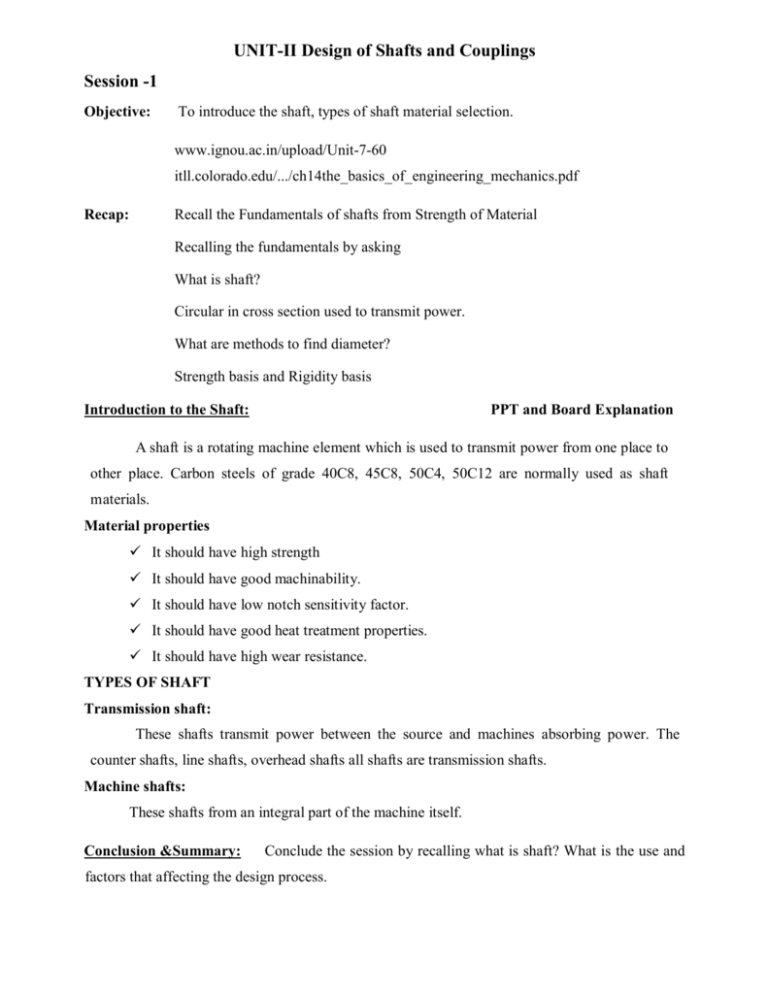

Shaft is a common machine element which is used to transmit rotary motion or torque. Shafts Axles and Spindles A shaft is a rotating member usually of circular cross-section solid or hollow which transmits power and rotational motion. Ad Download 100s of Presentations Graphic Assets Fonts Icons More.

Section VI Shaft Design Shaft. Find bending moments from gears pulleys or sprockets that are. RameshSingh Introduction Torque and Power Transmission Most of rotary prime movers either motors or turbines use shaft to.

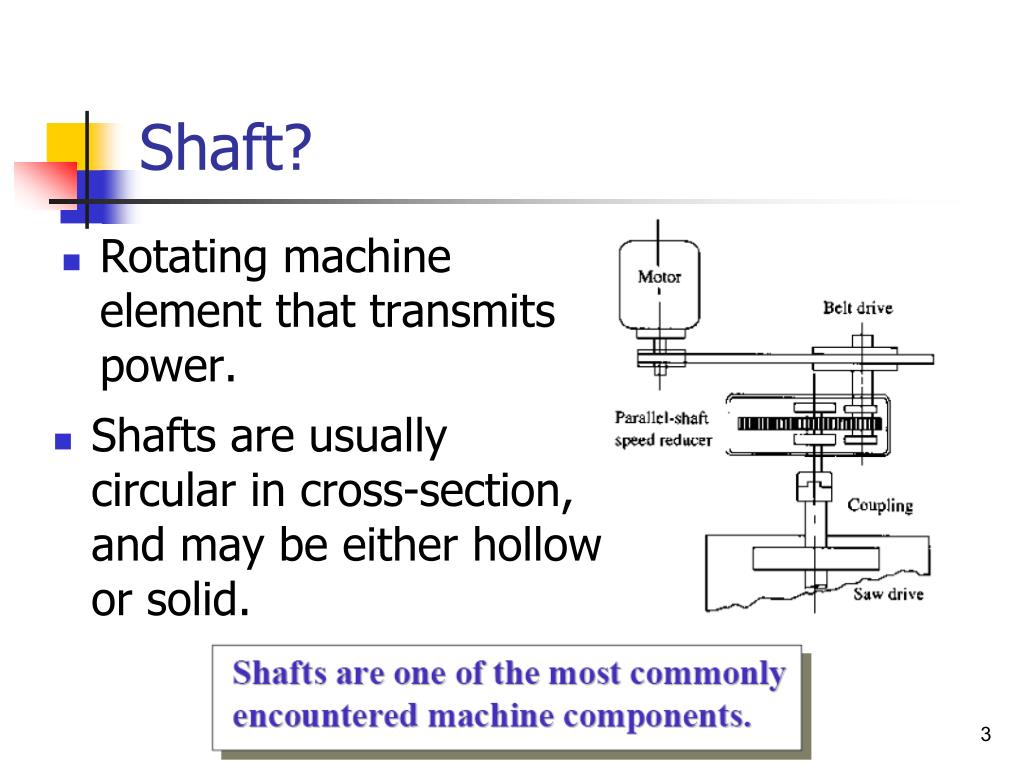

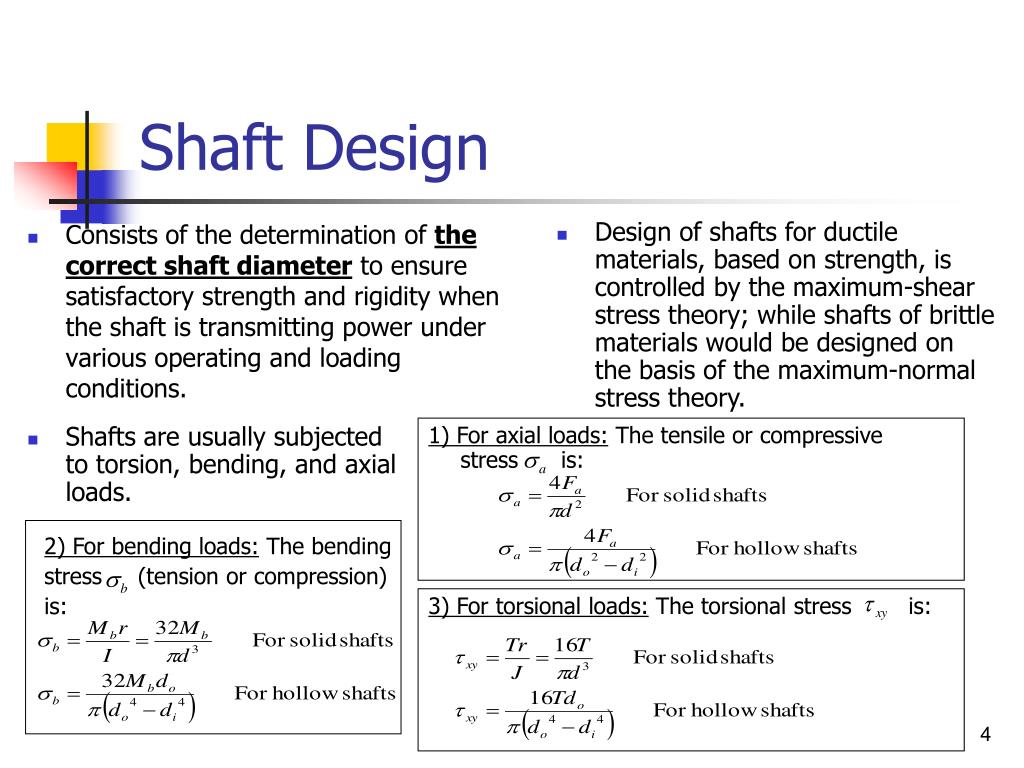

The number of tubular pieces and the joints depends on the distance. Combined bending and torsion loads on shaft. Shaft Design ASME Shaft Equations Design of Shaft for Torsional Rigidity Standard Sizes of Shafts Bending and Torsional Moments.

Shaft Design for Stress Shaft Stresses Figure 621 Page 296 Notch-sensitivity curves for materials in reversed torsion. Determine the design of the power-transmitting components or other devices that will be mounted on the. Design of Shafts 1.

It generally has circular cross-section and can be. The shaft for a mixer especially a. A projection on a rotating part in machinery designed to make sliding contact with another part while rotating and to.

Ti 1 α λ L r 1 1 5 1 0 0 0 4 4 λ λ 2 s yc α 2 λ 115 π nE n 10 for hinged end. LESSON 14 DESIGN OF SHAFTS. First the design of the composite shaft and second the design of its coupling.

DESIGN MANUFACTURING OF CAMSHAFT INTRODUCTION CAM. They are simple to design highly ecient and relatively forgiving of mounting errors. Design of Shaft 18 Shaft design based on strength A i l stress Axial t continue.

There is absolutely no requirement of removing the crankshaft from the block and sending it to the workshop when RA Power Solutions is called into help support. Shaft design based on strengthShaft design based on strength Desii id h l i fign is carried out so that stress at any location of the shaft should not exceed material yielding. Determine the power or the torque to be transmitted by the shaft.

Axels are non rotating member carries no torque and it is used to support rotating. Shaft is a rotating member and it provides axis of rotation for gears pulley flywheels cranks sprockets.

Ppt Shaft Design Powerpoint Presentation Free Download Id 3955524

Ppt Shaft Design Powerpoint Presentation Free Download Id 3955524

Design Of Shaft Ppt Powerpoint

Topics Introduction Shaft Design Stresses And Loads On Shafts Ppt Video Online Download

Shafts And Shaft Components Ppt Download

Shafts And Shaft Components Ppt Download

Ppt Shaft Design Powerpoint Presentation Free Download Id 3955524

0 comments

Post a Comment